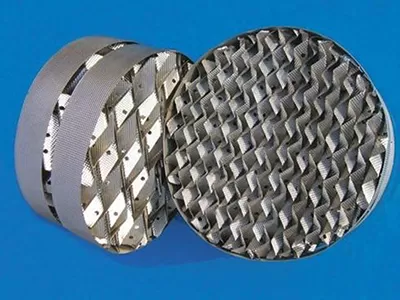

Is Structured Packing Toxic?

The toxicity of structured packing depends primarily on the materials from which it is manufactured, rather than its classification as "structured packing" itself. Structured packing, as a type of industrial separation material, is designed to facilitate gas-liquid mass transfer processes, and its inherent toxicity (or lack thereof) is determined by the specific substances used in its production.

Common materials for structured packing include metals (such as stainless steel, aluminum alloys), plastics (like polypropylene, polyvinyl chloride), and ceramics. Metal-based structured packing, when made from food-grade or industrial-grade stainless steel, is generally non-toxic and chemically stable, making it safe for use in industries like food processing, pharmaceuticals, and drinking water treatment. Ceramic structured packing is also inert and non-toxic, suitable for handling corrosive or high-temperature materials without leaching harmful substances.

Plastic structured packing, however, may raise toxicity concerns depending on the plastic type and application conditions. For example, some plastics might release harmful chemicals if exposed to extremely high temperatures or strong solvents, especially if they are not made from food-grade or chemical-resistant materials. But when selected appropriately—using plastics approved for specific industries (e.g., polypropylene in water treatment)—plastic structured packing can be non-toxic and safe for its intended use.

It is important to note that structured packing itself does not inherently produce toxicity during normal operation. Toxicity risks arise only if the material is incompatible with the process fluids (e.g., reacting with corrosive substances to form toxic byproducts) or if low-quality, uncertified materials are used. Manufacturers typically provide material safety data sheets (MSDS) for their packing products, specifying chemical resistance and safety guidelines to ensure proper and safe application.

In summary, structured packing is not inherently toxic. Its safety depends on material selection, compliance with industry standards, and compatibility with the process conditions. With appropriate material choices and proper use, structured packing operates safely in various industrial applications.