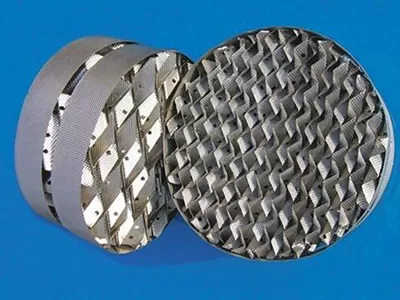

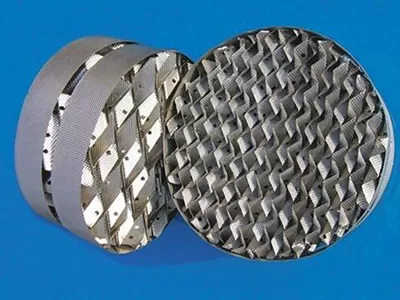

Yes, there is 500Y structured packing. In the classification system of structured packing, especially for the widely - used vertical corrugated packing, the number in the specification typically represents the specific surface area value, and the letter 'Y' indicates that the corrugation inclination angle is 45°. So, 500Y structured packing means this type of corrugated packing has a specific surface area of 500 m²/m³ and a corrugation inclination angle of 45°.

The 500Y structured packing, with its relatively large specific surface area, offers several advantages in industrial separation processes. The large specific surface area provides more contact area for gas - liquid or liquid - liquid phases. This enhanced contact promotes more efficient mass transfer, making it highly suitable for applications where high - precision separation is required, such as in the production of high - purity chemicals, pharmaceutical distillation processes, and fine - chemical separation. For instance, in the purification of certain heat - sensitive pharmaceutical intermediates, the 500Y structured packing can effectively separate target components from impurities under relatively mild operating conditions, reducing the risk of thermal degradation of the products due to its efficient mass - transfer performance.

Moreover, the 45° corrugation inclination angle of the 500Y structured packing contributes to a balanced performance in terms of fluid distribution and pressure drop. It allows for a relatively uniform flow of fluids through the packing structure, minimizing the occurrence of channeling or uneven flow phenomena. This results in stable operation and reliable separation efficiency during continuous industrial production. In large - scale distillation towers in the petrochemical industry, the use of 500Y structured packing can ensure high - quality separation of various hydrocarbon fractions, improving the overall efficiency of the refining process.

In terms of material selection, 500Y structured packing can be made from a variety of materials, including metals (such as stainless steel, aluminum alloys), plastics (like polypropylene), and ceramics. The choice of material depends on the specific process conditions, such as temperature, pressure, and the corrosiveness of the process fluids. For high - temperature and high - pressure applications in the petrochemical industry, metal - based 500Y structured packing, especially those made from high - grade stainless steel or nickel - based alloys, is often preferred due to their excellent heat resistance and mechanical strength. In contrast, for applications involving corrosive fluids at relatively low temperatures, plastic or ceramic 500Y structured packing may be more suitable to prevent corrosion and ensure long - term operation.