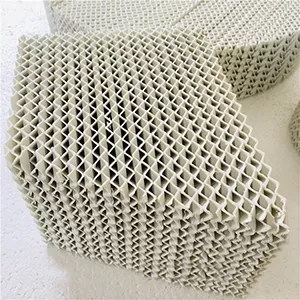

Can Ceramic Plate Corrugated structured packing Resist Hydrofluoric Acid?

Ceramic plate corrugated structured packing generally has poor resistance to hydrofluoric acid (HF) and is not suitable for applications involving this highly corrosive chemical. This limitation stems from the chemical composition of ceramics and their inherent reactivity with hydrofluoric acid.

Most ceramic materials, including those used in structured packing, are primarily composed of silica (SiO₂) or silicate compounds. Hydrofluoric acid is unique among acids in its ability to react with silica, a key component of ceramics, through the chemical reaction: SiO₂ + 4HF → SiF₄↑ + 2H₂O. This reaction dissolves the silica matrix of the ceramic, leading to gradual degradation of the material. Over time, exposure to hydrofluoric acid causes the ceramic surface to erode, lose structural integrity, and develop cracks or pitting. In severe cases, this can result in complete failure of the packing, compromising the efficiency and safety of the industrial separation process.

The extent of corrosion depends on factors such as the concentration of hydrofluoric acid, temperature, and duration of exposure. Even dilute hydrofluoric acid solutions can cause measurable damage to ceramic packing over prolonged contact, while concentrated or high-temperature HF streams accelerate the degradation process. This makes ceramic plate corrugated packing unsuitable for processes like HF alkylation, fluorine-containing gas absorption, or any separation task where hydrofluoric acid is present in the gas or liquid phases.

For applications requiring resistance to hydrofluoric acid, alternative materials are preferred. Fluoropolymer-based packings (e.g., PTFE) or metal alloys with high nickel and chromium content (such as Hastelloy) exhibit far better resistance to HF corrosion. These materials do not react with hydrofluoric acid under typical operating conditions, ensuring long-term performance and structural stability.

In summary, ceramic plate corrugated structured packing is not resistant to hydrofluoric acid due to the reactive nature of its silica-based composition with HF. When hydrofluoric acid is present in industrial separation processes, non-ceramic alternatives should be selected to avoid material degradation and maintain process efficiency.