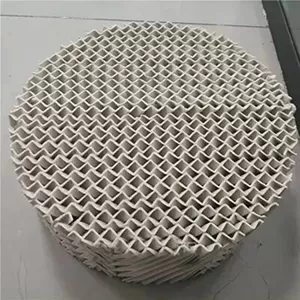

Is Ceramic structured packing Resistant to Alkalis?

Yes, ceramic structured packing generally exhibits good resistance to alkalis, making it a suitable choice for industrial separation processes involving alkaline media. Its alkali resistance stems from the inherent chemical properties of ceramic materials and their limited reactivity with most alkaline solutions under typical operating conditions.

Ceramic structured packing is primarily composed of inorganic materials such as alumina, silica, or magnesia-based ceramics. These materials are chemically inert to many alkalis, especially at moderate temperatures and concentrations. For example, high-alumina ceramics (with alumina content above 80%) show strong resistance to sodium hydroxide, potassium hydroxide, and other common alkaline solutions, as alumina reacts minimally with alkalis under normal process conditions. This inertness prevents degradation, dissolution, or structural damage that could compromise the packing’s performance.

The extent of alkali resistance, however, depends on several factors, including the type of ceramic material, alkali concentration, temperature, and exposure time. Silica-based ceramics, while resistant to low to moderate alkali concentrations, may react slowly with highly concentrated alkalis (e.g., molten sodium hydroxide) or at elevated temperatures, forming silicate compounds that can gradually erode the surface. In contrast, high-alumina or magnesia ceramics offer superior resistance even in more aggressive alkaline environments, making them preferred for applications involving high-concentration alkalis or high-temperature alkaline processes.

Another advantage of ceramic structured packing in alkaline environments is its stability under thermal cycling. Unlike some plastic packings that may soften or degrade in hot alkaline solutions, ceramic materials maintain their structural integrity and mechanical strength, ensuring long-term reliability. This stability is particularly valuable in industries such as chemical processing, wastewater treatment, and pulp and paper production, where alkaline conditions are common.

In summary, ceramic structured packing is generally resistant to alkalis, with performance varying by ceramic type and process conditions. High-alumina and magnesia-based ceramics, in particular, provide excellent alkali resistance, making them a reliable choice for separation processes involving alkaline media.