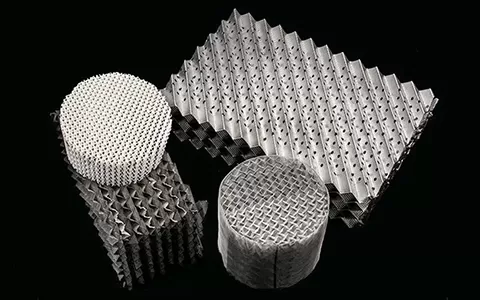

Mesh corrugated packing belongs to structured packing and is an important and widely used type among structured packings.

Its core characteristics conform to the definition of structured packing: it has a regular and ordered structure, composed of multiple corrugated mesh sheets arranged and assembled alternately at specific angles (usually 30° or 45°). The corrugation directions of adjacent sheets are opposite, forming a uniform and ordered channel structure. This regular arrangement makes the distribution of gas and liquid phases in the packing layer more uniform, avoiding problems such as channeling and bias flow that may occur in random packing.

At the same time, its "mesh" structure is formed by processing uniform meshes on the corrugated sheets, aiming to further increase the gas-liquid contact area, enhance mass transfer efficiency, and reduce flow resistance. This design not only retains the advantages of structured packing such as large specific surface area, low pressure drop, and high separation efficiency but also enhances the disturbance and contact effect of gas and liquid phases through the mesh structure. It is especially suitable for scenarios with strict requirements on mass transfer efficiency, such as precision separation, vacuum distillation, and thermal-sensitive material processing (such as in the petrochemical, pharmaceutical, food processing and other fields).

Therefore, mesh corrugated packing clearly belongs to the category of structured packing both in terms of structural form (regular arrangement) and classification attributes, and it is a performance-optimized version of traditional corrugated structured packing.