Structured packing is classified based on two core criteria: structural shape and material, which directly determine their performance characteristics and application scopes.

1. Classification by Structural Shape

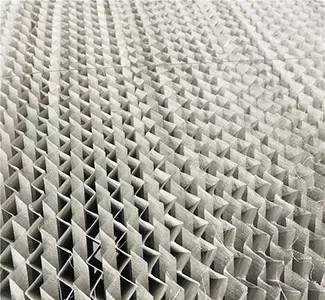

The most prominent distinction in structural shape lies in the form of packing units, with corrugated types being the most representative and widely used category.

- Corrugated structured packing: Its basic unit consists of corrugated sheets arranged in an orderly manner. Depending on the processing of the corrugated sheets, it can be further divided into:

- Orifice corrugated packing: Small holes are punched on the corrugated sheets to enhance gas-liquid contact and reduce flow resistance.

- Mesh corrugated packing: Uniform meshes are processed on the corrugated sheets to increase the specific surface area and strengthen mass transfer efficiency, making it suitable for precision separation scenarios.

The corrugated direction of adjacent sheets forms specific angles (usually 30° or 45°) and alternates in opposite directions, forming an ordered channel structure that ensures uniform gas-liquid distribution.

Other structural shapes, though less common, include grid-type and plate-type structured packing, which are designed for specific process requirements such as high throughput or low pressure drop.

2. Classification by Material

Materials of structured packing are selected based on the properties of the handled materials and operating conditions, mainly including:

- Metal materials: Such as stainless steel, carbon steel, and aluminum alloys, which offer high temperature resistance, pressure resistance, and mechanical strength. They are widely used in petrochemical, chemical engineering, and other industries with harsh operating conditions.

- Plastic materials: Including polypropylene, polyvinyl chloride, etc., which are corrosion-resistant and cost-effective, suitable for handling non-high-temperature, non-strongly oxidizing materials in industries like water treatment and food processing.

- Ceramic materials: Characterized by excellent corrosion resistance and high-temperature stability, they are applicable to scenarios involving strong acids, alkalis, or high-temperature environments, such as in the pharmaceutical and environmental protection fields.

In summary, the classification of structured packing based on structural shape and material provides a clear basis for selecting appropriate packing types in practical applications, ensuring optimal performance in separation processes.